When considering which products from cellular agriculture are already available on the market, and which cellular agriculture company raised the most money from investors, it may come as a surprise that the most active company is not the best-known industry player, Memphis Meats, but a company that produces dairy goods using precision fermentation.

The less visible opportunity

The less visible opportunity

Environmental, animal rights, and health concerns – all these issues that are relevant to industrialized meat products could be applied equally to industrialized milk and dairy products, although they are less prominently discussed in the media.

Cows spend their lives being constantly impregnated in order to produce milk. Instead of using bulls, the majority of dairy cows are now artificially inseminated. Antibiotics cure their infections, and they are treated with hormones designed to increase milk production. The cows are pushed hard, and when their production slackens after roughly three or four years, they are sold off for hamburger meat.[13] The public remains largely unaware of this gloomy inside picture of the milk and dairy industry.

At the same time, due to issues like lactose intolerance and milk allergy arising from the consumption of cow milk, there has been an increased demand for plant-based alternative kinds of milk around the world. Though they are popularly advertised as healthy and wholesome, little research has been done to improve our understanding of the nutritional implications of consuming these milk beverages in both the short and the long term.[14]

Furthermore, milk is the primary source of nutrition for babies before they are able to digest other types of food. Most infant formula is made with cow's milk that has been altered to resemble human breast milk. Globally, 87 percent of babies are fed formula at some point. Although baby formula in general is considered a healthy alternative, breast milk is always considered the best for babies.

According to a report by IMARC Group, the global dairy market reached a value of US$673.8 billion in 2018. Looking forward, IMARC expects the market to be worth US$1'032.7 billion by 2024.[15]

Certainly, there is a huge although not visible opportunity for more sustainable, safe, and ethical ways to produce milk and keep all its nutritious benefits. New developments in biotechnology are already making their way into the milk and dairy industry.

The nature of milk: An introduction

The nature of milk: An introduction

If we want to understand what cultured human milk or precision fermented milk is, we must first understand the nature of conventionally produced milk. In general food use, a useful definition can be found in the Codex Alimentarius.[16] The term “milk” has been defined as: “[…] the normal mammary secretion of milking animals obtained from one or more milkings without either addition to it or extraction from it, intended for consumption as liquid milk or for further processing”. The term “dairy” relates to animal milk and animal milk products.

The codex also states that “Foods shall be described or presented in such a manner as to ensure the correct use of dairy terms intended for milk and milk products, to protect consumers from being confused or misled and to ensure fair practices in the food trade” (Codex Alimentarius, 1999). The FDA and the EU Commission have established more refined definitions of milk and in particular dairy products.

Milk Composition

The composition of cow milk in the US is 87.7% water, 4.9% lactose (carbohydrate), 3.4% fat, 3.3% protein, and 0.7% minerals. Cow, goat, or sheep milk composition varies depending on the species and the breed (e.g., Holstein or Jersey cow); on the animal’s feed; and on the stage of lactation. In cow’s milk, approximately 82% of milk protein is casein, and the remaining 18% are whey proteins or serum. Milk proteins contain all nine essential amino acids that humans need.

The caseins in milk form complexes called micelles and will precipitate at a pH value of 4.6. Casein represents the basis for most cheeses. There are several types of casein proteins, such as α-s1, α-s2, β, and 6. Each is encoded by its own gene and has a specific amino acid composition and functional properties. The serum or whey proteins remain in solution if milk gets sour. The whey protein family consists of β-lactoglobulin (approx. 50%), α-lactalbumin (approx. 20%), blood serum albumin, immunoglobulins, lactoferrin, transferrin, and several other proteins and enzymes in minor quantities.[17]

Mature human breast milk is sweet since it contains approximately 70 g/l of carbohydrates, mostly lactose. Approximately 10% of the carbohydrates are human milk oligosaccharides (HMOs). HMOs are complex natural sugar molecules that are found uniquely in human milk. These sugars do not provide calories, since they cannot be digested by humans. As of today, more than 150 different complex oligosaccharides have been isolated from human milk.

HMOs have been recognized for their functional role in newborn and infant health since the late nineteenth century. HMOs have a prebiotic effect, influencing the development of the intestinal microbiome, protecting neonates from viral and bacterial infections, reducing the risk of allergies, and promoting brain development and neuronal activity. Some biotechnology companies are focusing on the field of precision fermentation of HMOs.

Precision fermentation

Precision fermentation

Unlike meat, milk is not made from animal cells. It is possible to produce identical protein to milk protein through precision fermentation without cows. Fermentation is the process of converting carbohydrates to alcohol or organic acids using microorganisms – yeasts or bacteria – under anaerobic conditions. Since ancient times, humans have exploited the fermentation process to produce alcoholic drinks such as wine, beer, and cider. Other widely consumed fermented foods include bread, yogurt, vinegar, olives, and cheese.

The term “precision fermentation” combines biotechnological fermentation with precision biology, allowing scientists to program micro-organisms to produce almost any complex organic molecule needed.

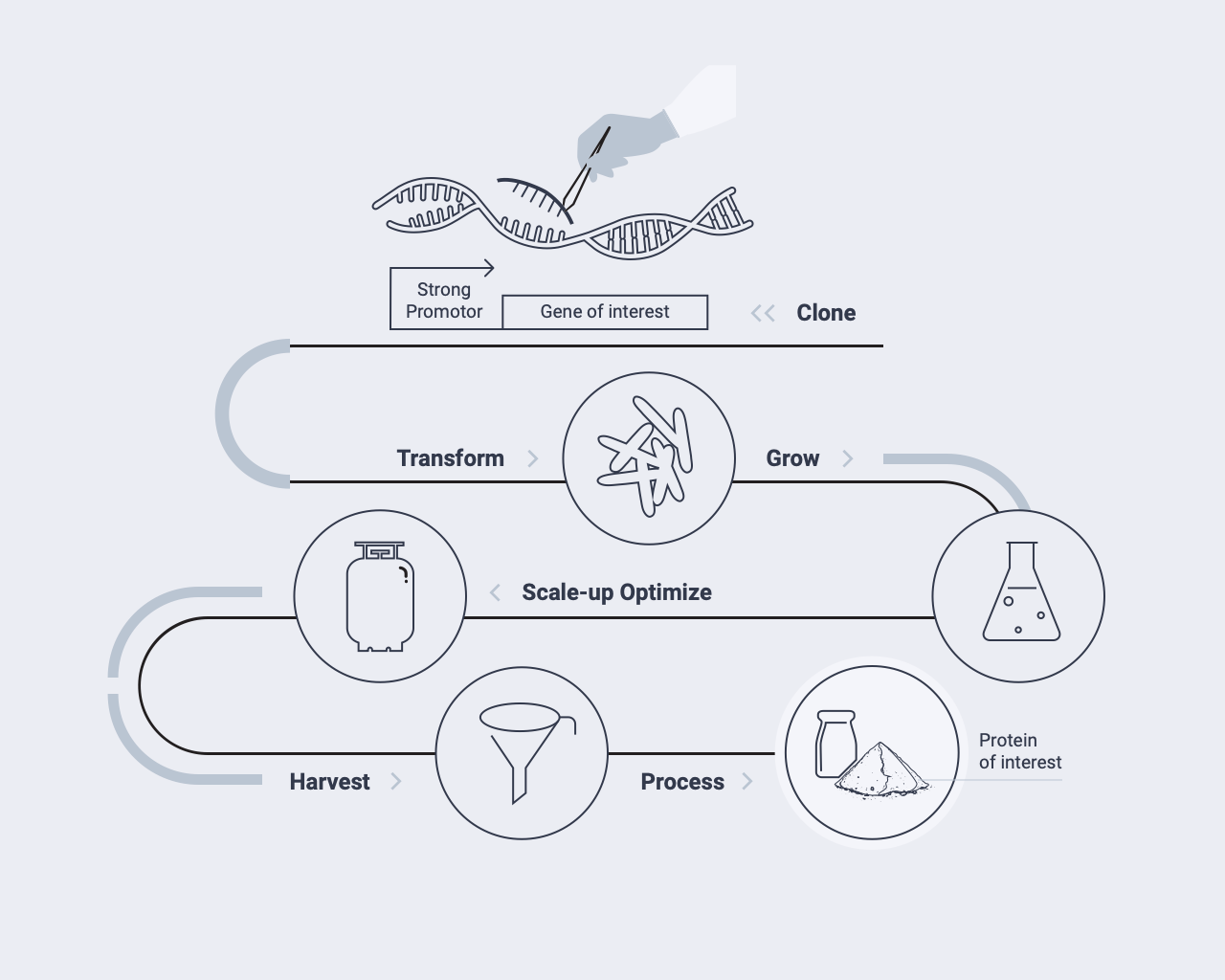

More than 70 years ago, the filamentous ascomycete Trichoderma reesei was isolated on the Solomon Islands due to its ability to degrade and thrive on fabrics containing cellulose. This fungus is now considered the leading production host for biorefinery enzymes.[18]

Originally, T. reesei was used in industry for the production of hydrolyzing enzymes, especially cellulases. The major cellulase cellobiohydrolase I (CBHI) protein can represent approximately 50% of the secreted protein and is encoded by a single copy gene. The strong CBH1 promoter is also suited for foreign protein production.

To produce so-called “foreign” or heterologous proteins, a gene of interest from another species can be cloned into T. reesei under the control of the strong CBH1 promoter or other promotors (see illustration below). The heterologous protein is typically also fused to an endogenous well-secreted carrier protein. The recombinant T. reesei production strain is then grown in a medium with cellulose, lignocellulose biomass, or sugars as relatively cheap substrate. It then overproduces and secretes the protein of interest.

Protein production in Trichoderma reesei

These high-production hosts are different from the original strain, since they are further optimized for better protein yield, e.g., due to lack of protease (proteolytic enzymes). Some studies report total secreted protein titers at unparalleled concentrations of 150 g/l. This highly remarkable value is more than four times higher than the total protein in cow’s milk (33 g/l), for example. In a final step, the protein of interest can be separated from the culture medium. This has been demonstrated by the expression of various biopharmaceuticals, such as interleukin-6 or enzymes used on a large scale in biotechnological processes.

Very recently, approaches such as the one described above have been applied for the production of food proteins, for instance in milk. Industrial filamentous fungi such as T. reesei and others have been generally regarded as safe (GRAS), which means they are not only a safe production organism of natural enzymes, but also a safe host for other harmless recombinant gene products.[20]

Milk proteins and sugars from precision fermentation

As listed in the table of companies, Perfect Day and Legendairyfoods state on their websites that they produce or plan to produce cow milk whey protein(s), while New Culture and Change Foods make cow milk casein(s). Perfect Day and Legendairyfoods also say they use T. reesei as production host.

Perfect Day, a start-up based in Berkeley, California, is the leading company to produce dairy protein using precision fermentation technology. The company received a GRAS notice for cow beta-lactoglobulin in 2019 (GRAS Notice No. 863) [21], indicating that this fermentation process can generate safe food products. Perfect Day also used this letter to conclude that “the protein characterization data shows that the sequence of β-lactoglobulin produced by fermentation is identical to commercially available bovine-produced β-lactoglobulin”. This means that the milk produced through the precision fermentation process is essentially the same as milk from a cow.

In July 2019, Perfect Day became the first cellular agriculture food company to launch a product with a limited release of the first animal-free dairy ice cream. Since then, Perfect Day has managed to scale up and reduce cost. In May 2020, Perfect Day announced that the company had partnered with Smitten Ice Cream to launch an animal-free dairy ice cream. This product, “N’Ice Cream”, was priced at US$12 per pint, which is on par with other existing high-end conventional ice cream products.

Some companies such as Jennewein, Sugarlogix, or Glycom address the production of individual sugar components of human breast milk. Sugarlogix claims to produce human milk oligosaccharides (HMOs) in yeast. Another company working on precision fermentation-based milk is Helaina, which is working to produce “lab-made breast milk”. The company is working on producing a composition that is very close to human breast milk with precision fermentation technology. Their aim is to offer a better alternative to milk formula.

Example of intellectual property

The key assets in precision fermentation are the producing strains of microorganisms and the precision fermentation/biotechnological production processes. On these, relatively little reliable and detailed information is publicly accessible. To get a better idea of the approaches involved, we looked at publicly available patents from Perfect Day, Inc. (see table of featured patents below). Although the Perfect Day website describes their products as being based on recombinant whey protein , their patent portfolio is much broader and also covers casein protein hybrid products and methods related to the production host.

| Patent Number | Title |

|---|---|

| US9924728B2 | Food compositions comprising one or both of recombinant beta-lactoglobulin protein and recombinant alpha-lactalbumin protein |

| WO2016029193A1 | Compositions comprising a casein and methods of producing the same |

| WO2018039632A1 | Food products comprising milk proteins and non-animal proteins, and methods of producing the same |

| WO2019213155A1 | Recombinant milk protein polymers |

| WO2020081789A1 | Recombinant components and compositions for use in food products |

| WO2020061503A1 | Methods and compositions for producing homokaryotic filamentous fungal cells |

Cell-based human milk

Cell-based human milk

Milk is a low-price commodity. According to a report by the US Department of Agriculture, the average retail price of conventional whole milk is US$3.55 per gallon.[22] It may not be commercially viable to produce conventional milk through top-notch cell culture technology. However, there is a special type of milk that is attracting entrepreneurs – human milk.

TurtleTree Labs, a Singapore based start-up, claims to be the world’s first cell-based milk company. “Cell-based milk is created by extracting stem cells of the milk of mammals. We then proliferate these cells, which means we grow them to a large number, and we’ll morph them into mammary gland cells. The cells will be put in lactation media and when they start to lactate, we’ll filter out the cells, so we’ll get the end product, which is milk,” Fengru Lin, co-founder of TurtleTree Labs, told media during a recent interview.

Although this method can be used to create all mammalian milk, TurtleTree Labs has set its sights on human breast milk as the company’s first product due to its high value and unique market potential. The company has been able to produce milk in its lab and will be focusing on scaling up. Although TurtleTree Labs wants to disrupt the infant formula industry, it wishes to do so through partnerships with existing major brands like Nestlé or Danone. “Our predicted time to start B2B collaboration would be Q3/4 2021. We plan to co-develop products with the industry which they would ultimately go to market with. We may not see the product out on shelf to consumers within a couple of years, but co-development would start as early as Q3 2021,” Lin told Supertrends in an e-mail interview.

Breast milk competition

TurtleTree Labs is not the only company that is working on cell-based breast milk. BIOMILQ, a US startup, also wants to tackle the problems of breastfeeding. BIOMILQ has its own patent-pending technology to culture mammary cells under conditions similar to mammary glands and to use these cells to produce milk with the same composition as breast milk. What is interesting about BIOMILQ is that besides working on a product for the mass market, they are exploring the possibility of an individualised high-end market. The hypothesis is that BIOMILQ will collect cells from the mammary gland of a pregnant woman, transfer them to its facility and produce milk from those cells. No date has been set for the product launch for BIOMILQ, although the company has said that “we don’t see cultured breast milk on store shelves any time soon”.

In the summer of 2020, all three abovementioned companies working on cultured milk received significant funding. BIOMILQ and TurtleTree Labs raised US$3.5 million and US$3.2 million, respectively. In July 2020, Perfect Day announced the expansion of its Series C round to US$300 million, making it the largest funding round to date for a cellular agriculture company.

Cultured milk: Strengths, Weaknesses, Opportunities, Threats

Cultured milk: Strengths, Weaknesses, Opportunities, Threats

In support of the discussion, we plotted a SWOT analysis (see below). Specific technological and product safety challenges exist for human mammary gland cell culture-based milk (BIOMILQ). Some of them have already been discussed in the context of meat based on cell culture (see section 4.3 in this report), namely, the potential need to deploy antibiotics and animal-based serum in the cell culture medium until media become available that are devoid of antibiotics and animal components.

Potentially harmful components of the medium itself or added antibiotics might be necessary to ensure a sterile cell culture, but should not be present in the final product. Human milk from cell culture is expected to be consumed by the particularly vulnerable group of newborns and infants. In addition, there is a question mark regarding the scalability of the approach as it relates to the availability of human mammalian gland cells. For human and cow milk from cell culture, the separation of milk components from the medium might prove technically challenging as well. On the positive side, human breast milk from cell culture can be regarded as a unique, high-priced niche market product once it becomes commercially available.

Bovine cell culture-based milk or milk proteins from precision fermentation are targeted at different customer profiles, and a much broader market and use on very diverse hybrid products. Of all the companies we studied for this publication, Perfect Day, Inc. seems to be most mature in terms of actively producing and selling precision fermentation-derived cow milk protein-based products such as ice cream.

| Strengths |

|---|

| Unique approach |

| Niche product |

| Weaknesses |

|---|

| Separation of milk and medium |

| Does not contain mother's antibodies and other compounds |

| Opportunities |

|---|

| Might be closer to natural breast milk compared to current human milk surrogate products |

| Threats |

|---|

| Scalability requirements related to specifically vulnerable consumers |

| Strengths |

|---|

| Products available |

| Safe products |

| Scalability |

| Price competitiveness |

| Animal-free |

| Defined milk products |

| Weaknesses |

|---|

| Few proteins compared to the more complex set of milk proteins |

| Opportunities |

|---|

| More/other final products can be created by processing and/or creating hybrid products |

| Strengths |

|---|

| Products available |

| Safe products |

| Scalability |

| Price competitiveness |

| Animal free |

| Weaknesses |

|---|

| Relatively few HMOs compared to highly complex set of natural HMOs (>150) |

| Opportunities |

|---|

| Can be used to improve pediatric formulations |

Beside milk proteins, other edible proteins can also be produced by precision fermentation, including egg white (Clarafoods), the soy hemoprotein, which is used as the key “meaty” ingredient of plant-based meat (Impossible Foods), or proteins that can be used for gummy bears or cosmetics such as collagen and elastin (Geltor).

In summary, precision fermentation in highly productive microorganisms such as T. reesei holds huge promise and has the potential to provide sufficient, cheap, and safe food proteins for mankind, milk proteins included. We are on the threshold of a biotechnological revolution driven by precision fermentation. The properties and nutritional value of conventionally produced milk and dairy products are well understood. The nutritional value of foods based on a limited number of further proteins remains to be assessed. Additionally, the price of precision fermentation products has to decrease. “The cost to produce a single molecule using precision fermentation has fallen from $1 million per kilogram in 2000, to about $100 today [September 2019]. Assuming existing technologies and using well-established cost curves, […] costs will fall below $10 per kilogram by 2025, and […] proteins will be five times cheaper than traditional animal proteins by 2030 and 10 times cheaper by 2035”, according to the RethinX report Rethinking Food and Agriculture 2020-2030 [23]. Even if this projection might be overoptimistic, it is still clear that precision fermentation is a megatrend that will disrupt the way food proteins and other proteins are currently produced.

The Future of Milk and Dairy Products

The Future of Milk and Dairy Products

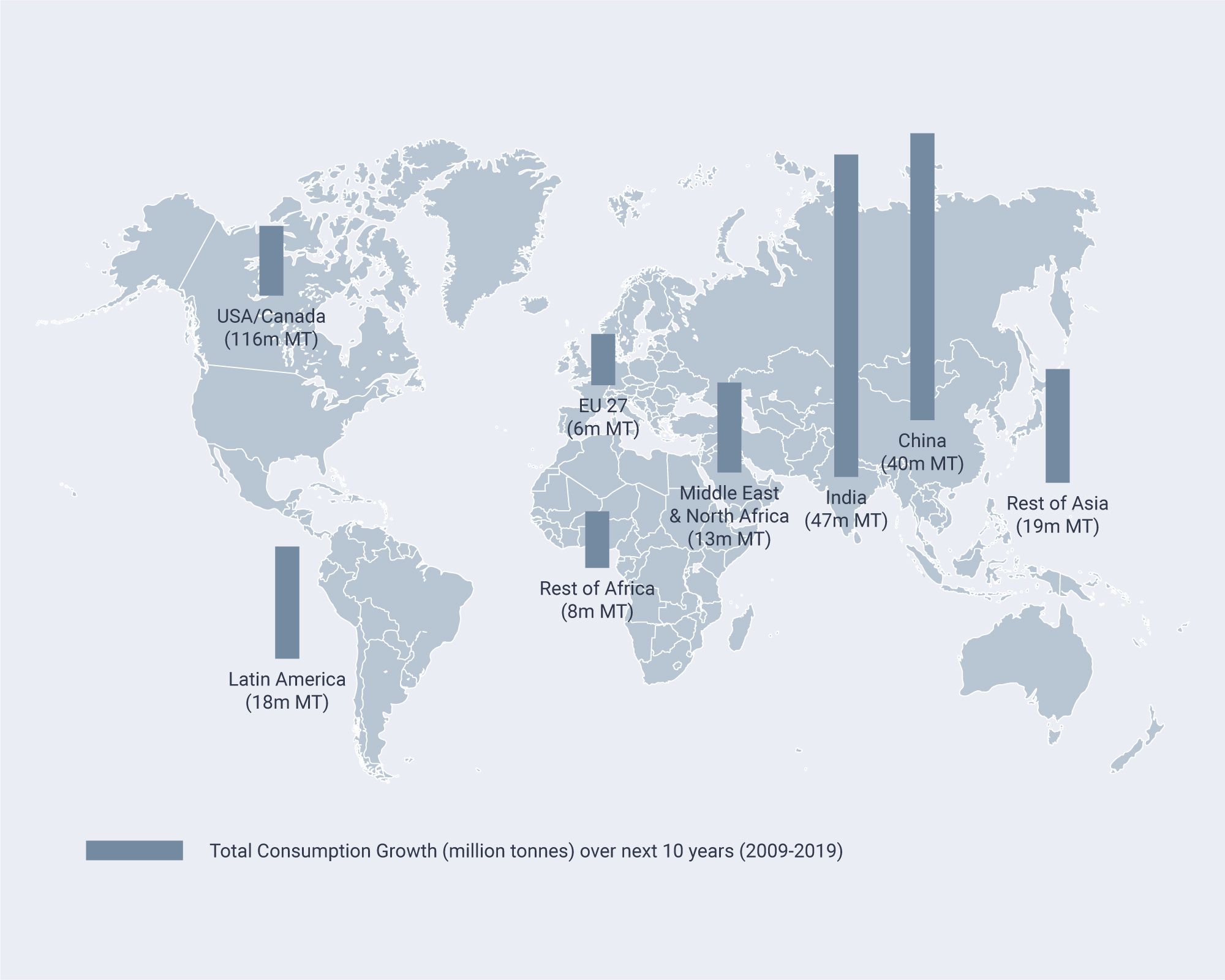

The global dairy market will continue to enjoy strong growth prospects in the coming years. Beneath the strong demand is an unbalanced growth. The developed country markets of North America and Europe are no longer the dominant drivers of dairy demand. The demand growth is mainly driven by Asia (mainly China and India), the Middle East, and Latin America.

By using precision fermentation or cell-based technology, milk and dairy products can be produced more locally, in the places where they are needed the most. Residents of areas that are unsuitable for livestock farming will be able to build their own facilities to become animal-free dairy protein producers.

Other than in ice cream, milk protein produced with precision fermentation can be used in almost all kinds of dairy products. Perfect Day released several images highlighting that their flora-based dairy proteins can be used across a range of products, from a glass of milk to different types of cheese.

The day may not be far off when people around the world can enjoy a scoop of ice cream, or cheese on a slice of pizza, made with milk proteins produced through precision fermentation in a factory near them.

References

[13] Kurlansky, M. 2014. Inside the milk machine: How modern dairy works. Modern Farmer, 17 March 2014. https://modernfarmer.com/2014/03/real-talk-milk/ (last accessed 1 September 2020).

[14] Vanga, S.K. and R. Vijaya 2018. How well do plant based alternatives fare nutritionally compared to cow’s milk? Journal of Food Science and Technology 55(1): 10-20.

[15] Global Dairy Market Size, Industry Report and Outlook 2019-2024. Wired Release, 19 February 2020.

[16] Codex Alimentarius Commission. General Standard for the Use of Dairy Terms 206-1999 (PDF), accessed September 2020. See also http://www.fao.org/fao-who-codexalimentarius/codex-texts/dbs/vetdrugs/glossary/en/.

[17] Cornell University, http://www.milkfacts.info (last accessed September 2020).

[18] Bischof, R.H. et al. 2016. Cellulases and beyond: The first 70 years of the enzyme producer Trichoderma reesei. Microbial Cell Factories 15(106)

[19] Picture taken from https://de.wikipedia.org/wiki/Trichoderma_reesei

[20] Nevalainen H. et al. 1994. On the safety of Trichoderma reesei. Journal of Biotechnology 37(3):193-200.

[21] US Food and Drug Administration (FDA) 2018. GRAS Notice (GRN) No. 863 for Non-Animal Whey Protein from Fermentation by Trichoderma reesei. https://www.fda.gov/food/generally-recognized-safe-gras/gras-notice-inventory (last accessed 12 October 2020).

[22] United States Department of Agriculture 2020. Retail Milk Prices Report.

[23] Tubb, C. and T. Seba 2019. Rethinking Food and Agriculture 2020-2030. The Second Domestication of Plants and Animals, the Disruption of the Cow, and the Collapse of Industrial Livestock Farming. A RethinkX Sector Disruption Report, September 2019.